-

Posts

123 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by MINNOWNITE

-

-

What brand/weight does everyone use? I am looking into tuf line micro lead. That way I can run 10 color where i ran 7 color before.

lb size is same price point. So why would you go 18lb vs 27lb. its .001" bigger. And the same price. I fish erie walleye and ontario eyes.

Thanks!

Waldo

-

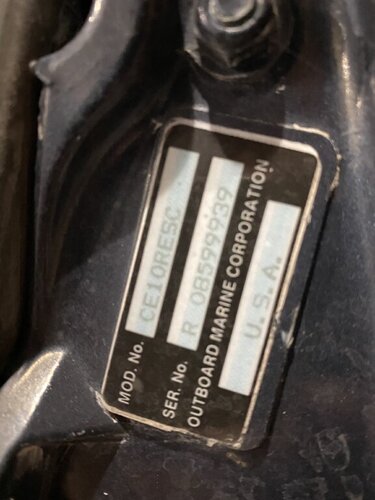

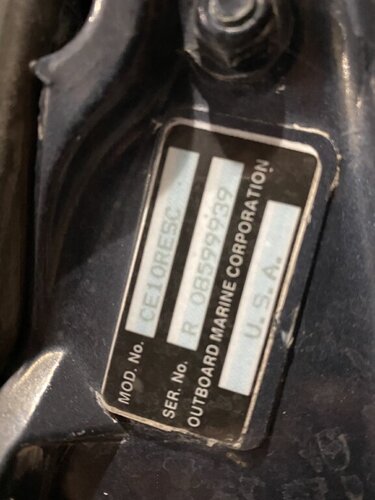

So got it all back together and trying to set the timing now. I followed oem specs. cyl 1 tdc. rotor pointing toward cyl 1. but wont fire. got spark. got fuel. Going to get a new cap and rotor today. Any idea what i'm missing?

-

1 hour ago, bettieanne said:

Minnow

I live in kendall, ny. West side of rochester. Tyee, I looking for marine grade. Had it on my crestline and loved it, textured for anti slip.

Sent from my SM-J327V using Lake Ontario United mobile app

Ok, I have a few providers here in Ontario. Bit of a hike for you lol

-

Where are you located?

-

how much line do you leave between the segments?

-

I plan on launching my planer boards this spring/summer. They will pull just as hard as aurora lites and Amish for a fraction of the price. I will have large for planer mast. Also by Fall 2020 i plan on having Good inline boards.

Minnownite Fishing Products

-

-

called trollmaster. Its a error on amazon's end. It is just a installation kit

-

This pricing seem wrong or am i missing something?

https://www.amazon.com/TrollMaster-TM200HWKIT-Hardware-Honda-1980-2000/dp/B07DTHXMHW

-

So between the trollmaster, itroll, and controlking,

Do these only allow you to set spot on the throttle and it holds it there? or will it maintain a speed?

example, going with current at a #4 setting, to maintain wanted trolling speed. If you turn against current would you need to amp up to a #6or#7 to get the desired speed or does it have a gps built in to get the desired speed. Hope that wasnt too wordy

-

following as i would also like this feature but have an older kicker.

-

-

Just now, dbitting said:

I actually have a OMC 4.3l block that just a crack in it looks like yours and i am deciding what to do with it

Hopefully you found some answers here. Once i use mine a few times i'll report back. and after a year if i remember

-

all good guys! any advice is always appreciated. even after the fact. Who knows joe blow in 3 years will be reading this post and learn something for himself!

-

Funny how i get all these suggestions after I already repaired it and installed it into the boat. But thank you never the less!

-

4 minutes ago, Zinger11 said:

If the motor is out of the boat would you be better off brazing it instead of jb weld ?

Sent from my SM-G970U using Lake Ontario United mobile app

it was too big of a crack and too close to the head. also for the price to get it welded vs a new block was too close. $5-600 to get it welded. $1200 for a bare block. $1700 by the time its in the boat. $20 worth of JB weld. $80 worth of gaskets. worth a shot i figure

-

What i ended up doing is going JB weld. hopefully it holds for a few years when i can afford to replace the engine. i ended up drilling the cracks and V grooving the crack. i did 3 applications of JB weld. Put the engine on a engine stand so i can work on a level surface. first 2 applications were light and forced into the crack. The 3rd application was heavy with drywall tape mesh. (seen it on a forum, figured couldnt hurt too much lol) all put back together and almost installed. just gotta wait for spring to see how it turned out

-

On 12/26/2019 at 2:26 PM, outback kennels said:

i got same boat i have a pump tht went to live well i hooke up for washdown

Sent from my iPhone using Lake Ontario United mobile appHow did you get the water back out?

-

I would reccomend cleaning the seams, rivets. and using urethane. Then do a bed liner product. either Rhino or LineX. This urethane is unreal. flexible and will not come off. if you get it on your hand. a month later its still there.

-

Chances are if your boat has leaked for that amount of time your foam will be water logged. Does it have a hard time getting on plane? tow heavy? just feel heavy in general? That would be my first look. Because if it is waterlogged then theres no point in trying to just fix it on the outside. I would look at gutting it like @sstout I too have done 3 boats. 2 of which were water logged. Couldnt even get the boat on plane. it was sooooo heavy! After you gut it. I would take PRO FORM urethane. They use it to install windshields on vehicles. So you know its uv resistant. I would do every rivet and seam on the inside of the boat. Then create a tunnel for water to flow. with either pipe or ridged foam (not white) and then pour in foam. From the outside I have done the same. Sandblast around the seams and rivets. Be sure not to blast the glue out of the seams where the aluminum overlaps. Then again i would use the urethane. nice beads. smooth out. and paint. I think the Rhino liner is a good idea. I've thought of it. was just never in the budget.

And most importantly! cleanliness is key!!! Make sure everything is perfectly clean before you apply any type of glue, sealer, paint ect. you can buy the best stuff on the market and it wont hold if it isnt clean

-

i'll send you a pm so we dont take up everyone elses feeds! @Sunshine

-

Thats awsome! one of the modifications i would like to make this winter is the bimini. I find it too far back and too low. For myself its ok. i'm fairly short. But for my company it doesnt work to land a fish with it up. You have to duck under it to get back far enough. I would like to raise it a foot and or move it forward about 1'6".

Do you both have inboards or outboards on yours?

-

13 minutes ago, Sunshine said:

I got the same boat and love it. I see the striping is also missing on your side that is underneath where the gas vent is. It annoys me but I don't know if I can do anything about it.

Yessir i do agree! super annoying. I tried to polish the boat but the paint was so faded and thin I burnt through right away. So I plan on soda blasting it and painting it in the near future (next few years)

-

yeah that one. I guess that makes sense. Thanks!

leadcore brands

in Tackle and Techniques

Posted

Youve run 4 years on the same leadcore without changing it? do you run boards? if so do you segment or clip straight on the leadcore? or use elastic bands?