-

Posts

23 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by Pitch55

-

-

On 7/25/2021 at 10:15 PM, Pitch55 said:

Okay - new development - as we were cleaning / prepping the hatches and their edges for sealant as we decided to put a bead of sealant around the outer edge of all hatches and including the fuel cap mount/bracket. As we are cleaning it I'm showing my son how to do it thoroughly and suddenly he says - "hey dad - this black casing around the fuel cap - I can almost fit my pinky finger under it...." - so after I get over my WTF moment - and under closer inspection - he was right - a good 1/4" gap between that housing and the metal of the splash pan. So before we go ahead and put all kinds of sealant all over the maintenance hatches - we did a pretty thick bead all around this fuel cap housing - as you can see in the photo - the size is significant - and this seems very appropriate to the amount of water that seemed to be coming into the hull vs. a bit of water sneaking in around the maintenance hatches (which seem pretty good and tight). So that's the update with photos - going to let the sealant cure overnight and will see if it needs a 2nd coat to make sure any potential edge is sealed up, but will then do another water test like the video above and give updates - maybe something to check on your boats as well if you have a similar fuel cap housing in your splash pan.

So the update on the leaky splash pan / motor well is that once I put a significant bead of submersible Goop to beasically seal this huge gap around the fuel-cap housing, I did the same test as I did in the video above - filled the pan/well with 4" of water, and we got ZERO water going into the hull. I've seen on other models of Trackers as well as other makes of boats, typically this housing (black) is welded aluminum, not a cheap piece of nylon/plastic drilled into the hull which is why this probably isn't seen alot, but anyone who may be suspicious of their maintenance hatches leaking, maybe give this a look in their boat to make sure they don't have a 3/8" gap letting water free-flow into their hull if waves are coming into that area of the boat. Mystery solved!!

-

2

2

-

-

On 7/24/2021 at 3:08 PM, Frogger said:

Cody, I went with lithium as well. Ionics. Found out how to wake one up easily with the Noco if you need it. One issue I found for my cranking battery 135 amphr is it over charges from my kicker while trolling. Had to take my charging system off the 8hp. So I have 2 for electric trolling motor in 24v and my cranking battery doing everything else. Took out 140 lbs. crazy.

Sent from my iPhone using Lake Ontario United140lbs!!! That is my goal - over the next season or two is get down as much stern weight as I can!!!

-

On 7/24/2021 at 6:41 AM, codybuehler said:

Before you buy another hatch, try taking it off with all those little screws and sealing around the cover where it touched the aluminum with 3M 4200 sealant (Home depot carries it normally!). You could do 5200 but 4200 would be enough. Both are rated for submersion, but 42 is removable. Try Vaseline on the actual cover that twists off. I haven’t checked for a gasket on mine, but I’m assuming it has a small o-ring in that lid. If Vaseline is good enough to seal and lubricate the o-rings on my fish hawk probe, it’s good enough for a handhole cover from China! HahaOkay - new development - as we were cleaning / prepping the hatches and their edges for sealant as we decided to put a bead of sealant around the outer edge of all hatches and including the fuel cap mount/bracket. As we are cleaning it I'm showing my son how to do it thoroughly and suddenly he says - "hey dad - this black casing around the fuel cap - I can almost fit my pinky finger under it...." - so after I get over my WTF moment - and under closer inspection - he was right - a good 1/4" gap between that housing and the metal of the splash pan. So before we go ahead and put all kinds of sealant all over the maintenance hatches - we did a pretty thick bead all around this fuel cap housing - as you can see in the photo - the size is significant - and this seems very appropriate to the amount of water that seemed to be coming into the hull vs. a bit of water sneaking in around the maintenance hatches (which seem pretty good and tight). So that's the update with photos - going to let the sealant cure overnight and will see if it needs a 2nd coat to make sure any potential edge is sealed up, but will then do another water test like the video above and give updates - maybe something to check on your boats as well if you have a similar fuel cap housing in your splash pan.

-

4 hours ago, codybuehler said:

The Dakota Litiums are good in theory. But! I just put those in 2 weeks ago. (Watch for discounts. They have codes) I got my pair of 100Ah lithium’s for $1450. You are correct with a new charger also. Noco genius makes a 10amp x 2 channel. The one tracker has in there is only a 5 amp x 2 so it is a big upgrade for recharge time!

Now the negative. Ran them in a 24V lineup series for maybe 8 hours and my trolling motor stopped working. Acted like the breaker popped open. Left the water on day 1 of a 3 day Lake O trip and checked them with a meter. 1 battery read 13.5volts, the other read 0.18volts. No bueno. Called customer service and got a voicemail so I left a message. Never got a call back. Sent an email to support and it was a day later I got a response. Meanwhile I ran to Advance auto and bought 2 new 27 series deepcycles to toss in and get the next 2 days back and not have to head 4 hours home to get the deep cycles I took out to put in Lithium. $240 I won’t see again except for those 2 new batteries I had to buy up in Pulaski.

Turns out it was the Battery Monitor System built into the lithium batteries had tripped for whatever reason. To reset it you have to either a/ hook it onto a not-smart charger (ie not a Noco that is onboard the boat) or b/ flash the terminals with another 12volt source. I knew the battery had this BMS to balance the cells and protect against whatever it protects against, but it could cause issues being too smart of a circuit.

I will say for the 8 hours they worked right it was a constant voltage at my trolling motor with no issues. Maybe it was in my head, but it did seem zippier. The one battery that didn’t fault was probably still around 90% capacity after 6 hours. I believe it would go 2 days at 4.5-5 speed on my Terrova. I’m putting the lithium back in this weekend and carrying a 12 volt spare source or jumper cables to flash the battery if it does it again.

Will be interested to hear if there was any reason it tripped, and if voyages 3,4,5 are all good without incident! Fingers crossed!

-

1

1

-

-

1 hour ago, codybuehler said:

So I stand a bit corrected here. Tracker riveted the covers on, not screwed. To reseal these you’ll be drilling rivets and re-riveting or screwing the covers.

I also noted one of the drain holes has a loose insert. I’m sure that’s letting water in mine as well. I’m sure a few smacks in a rubber pallet will tighten it right up.Part of me wants to caulk the crap out of those hatches and let the dealer figure it out whenever the boat has to go in but with my luck they'll break it and i'll have to pay to replace - haha! Going to try the vaseline on the inside threads for sure to see if that slows/stops it - going to also try a very thin bead of glue or something around the outside of the rivetted disc to hopefully get a bit better seal there as well but i think in practice - i'll have plugs in both those splash-pan holes when out fishing - and pop one out when driving to/from spots or the dock to allow it to drain. At least this is easy to test over and over again in the driveway even though very annoying lol

-

5 hours ago, codybuehler said:

That is a pile of added in weight. But the redundancy the awesome.

Why did you go with the 31’s over the stock 27’s? Do you get to places you can’t recharge your batteries? I could go almost 2 fishing days (15-16 hours) on the 27’s it came with after 2 seasons of fishing before they would get low enough to be an issue. Water that close to the drains it would have been in there a lot with just a small riffle on the water.My first season with the big boat I was still trying to use it like my smaller boat that I used for trolling - and only used the electric. Pulling that big ship at 1.7mph I was running out of juice in like 2.5 hours on the big lake so I thought maybe upgrade the batteries a bit (expensive lesson vs. doing that AND getting a kicker). Now this season I've barely used the electric so when those G31s die I will get 27s again as well and maybe will do that next season anyway - and roll those 31s into our camp solar system. I really like the Dakota Lithium system - less than half the weight and double the power (so they say) - but the price was a bit much to swallow - $1600+ for the 24V circuit and then you'd need a new on-board charger as well.

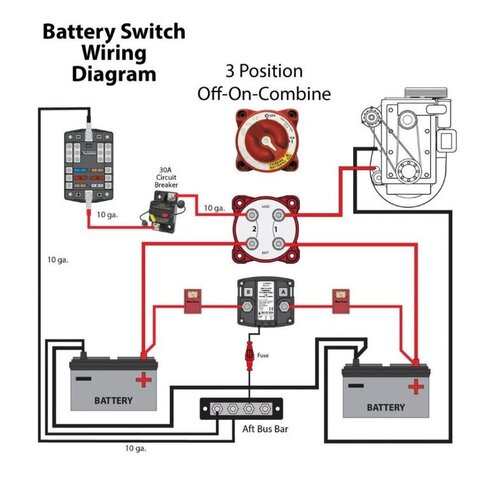

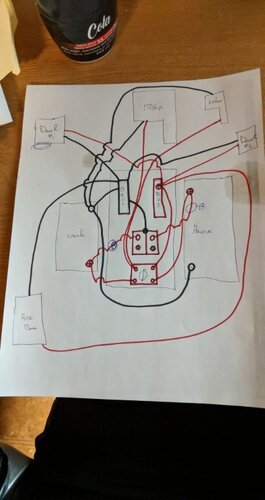

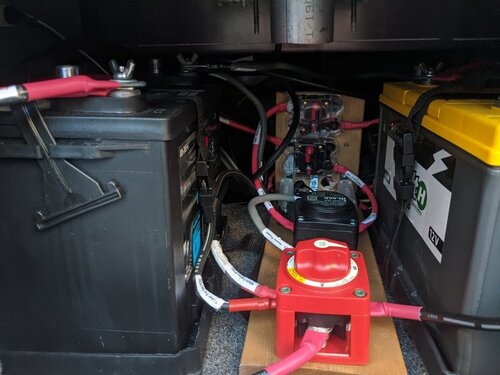

The redundancy and security of having the two batteries (house / crank) has already paid off - i'll include some pics - was a bit of a job wiring it but I love wiring and that kinda thing - but put in the isolator switch and an ACR unit (charging relay) so the big engines charge both batteries all the time - and if one ever dies on the water - switch goes to "combine" and jumps the ignition batt and we get rolling.

Really tight space for us to work but you'll see my fun I had going from factory diagram / specs - to my version - to the finished / wired product installed. Annoying that I have to pull it all out every fall to store the boat (no heated garage) - but it is what it is.

-

1

1

-

-

Full disclosure - you can see a bit of pollen on the hull showing the water line very close to the drain hole of the well / pan - this is largely due to fishing with a large gas tank in the stern, combined with: switching Group 27 batteries for the trolling motor with Group 31s which are bigger, I've added the kicker motor on the port side, as well as adding a group 27 deep cycle / hybrid battery as well for the electrical system (now running a house / crank battery dual circuit vs. just the 1 battery that came stock) - so significant weight added to the stern, so definitely contributes to the fact that the stern sits lower in the water, but is NOT an excuse for Targa making leaky maintenance hatches that almost resulted in teh sinking of my boat while sitting at the dock while on vacation. Would welcome any thoughts on how we / I approach Tracker on this. Again - thanks in advance for any insights / ideas folks.

-

1

1

-

-

Hey Brad - my auto-bilge is also delivered and being prepped for installation. If anyone is reading this and saw Cody's theory above, just let it be known that he is 100% correct about the maintenance covers being the issue. At this point I am not sure if both are leaking or if it is more one than the other - I will be testing this but see this video I've uploaded where I've filled up the splash-pan / motor-well with water and you can immediately see water pouring steady like a faucet out the main hull drain plug. I am going to test which maintenance hatch is leaking the most / worst to try and seal, but recognize I can't just caulk it permanently as we may need access at some point for maintenance - but for now with those with Targa's having a leak and you're not sure why - give this a gander:

-

1

1

-

-

As always - thanks for the insight guys. Cody funny you mention the splash pan/motor well as my 11yr old asked exactly that - if the water could be coming in through those access ports / black circular hatches - they fit so snugly it just seems so unlikely that the water we are pumping out while fishing could be coming in there, but your description above is to a tee the exact same as what I'm seeing - 2-3 hours of trolling on the big lake and as you say - turn on the bilge for 30s or so just to clear the bottom out when i think of it and/or before blasting off to move to a new spot to shed some weight. I'm going to fill that splash pan just below the gas-cap as you suggested tonight and will report back to the group what I find, I'll also be putting the hose on any / all drain holes and through-hull ports to see if any of those could be the culprits as well because as you say - leaving the boat overnight bucking for 12-18 hours in 18" waves shouldn't almost sink the boat.

-

Hey Guys - hope the 2021 season is treating everyone great and all is going well. I know this is the kicker thread but I also know there are us Tracker guys in here so it is your brains I want to pick for ideas.

Off and on I've encountered having water in the hull after running the livewells - and all the forums all say the same thing - loose fitting on the intake hose or the drain hose etc etc. which makes sense as I have seen lots of complaints about tracker's quality on the inner workings (wiring / hoses / etc.). Anyway - we went on a vacation last week - boat tied up to the dock - had some waves (inland lake) - maybe 1 footers at most rocking the boat all night - minimal rain. Down to the dock in the AM to get her ready to fish and flip the bilge pump on (no auto bilge for god knows what reason) just in case there is some rain water - and the bilge runs for 5mins - and I open the floor compartment - FULL of water. so that was my WTF moment - wasn't using the livewells - didn't rain that hard (barely any at all) - not wavy enough to splash over the back and even so - very small wiring hole to allow splashing water in - not enough to put 100 gallons of water in the hull overnight.

I have it home and here was my troubleshooting process once on the trailer in the driveway: Hook up garden hose to each of the livewell intakes - put the pumps on pull water into the wells with the drain plugs in - fill the wells - let them sit for 10 watch for any water in the back of the hull - nada. Pull the drain plugs and watch for any water leaking into the hull vs. out of the drains - nada. So I put the main boat plug in - and fill the bottom of the hull with water and let the boat sit on the trailer for 20mins just to make sure it's not a hull issue. Not a drop of water in the driveway. So now I'm stumped - my next idea is to put the boat in the water on a calm day/bay and open those back discs in the splash pan to look inside to see if there is anything leaking (transom bolts / etc.) because I cannot figure out where this water is coming from.......any thoughts / ideas / guesses are welcome fellow Tracker guys!

Thanks in advance!

-

3 minutes ago, Rookie Fisherman said:

Pitch,

I removed the back deck to access the inside off the transom and through bolted with washers & locking nuts.

2 Bolts and tighten the clamps on the motor.

Happy New Year!

10-4 - I was afraid of that (trying to avoid pulling up the deck if I can) - haha - but very much appreciate the info!!

-

On 10/2/2018 at 4:54 AM, Rookie Fisherman said:

Went through this same process a few years back. Opted to take a 2x2 piece of pressure treated wood (painted it black)Set it in the on top of the transom in the throat of the motor bracket mount. This raised the motor 1.5" and did not have to cut the carpet or the deck. Had no effect on operation of the motor.

Also to save spaced at the helm I mounted the fish hawk at the back of the boat on a bracket in the versa track.

Hey Rookie Fisherman - happy new year! I was looking at this option with my Tracker as well - but was curious about how you secured the motor to the transom. The riser works well for sure - I have my wood chunk all cut / treated, did you just use some stainless lag-screws to bolt the motor on to the transom/hull or did you even bother with that? I got a kicker with power trim / etc. so am thinking that even if I secure with a Jack Plate or the riser as you did - I'm still drilling into the transom to secure the motor to the transom. Anyway - if you think of it - shoot me a response - would very much appreciate it!

-

I actually lucked out - bought mine used from a guy listing it as "long" - but turns out it is an extra long shaft. Works great!

-

Am considering a fish hawk in the coming year(s) but am hoping since I'm only trying to do the motor right now it won't be a huge ordeal. I see the U-bolt being in the way for sure, and I was secretly hoping to be able to access the inside of the transom from those black threaded discs in the splash-pan to let me get in there to mount the motor, but the riser plate I'm looking at putting on to fill in the gap above the transom I may have to pull up the floor anyway - so we'll see when she comes out of storage this weekend. I'm fairly north so we're still dealing with ice - including an inch of snow from last night!!

-

it's the base model 150 merc 4-stroke (2018) - and yessir believe it's all hydraulic.

-

Hey Eric, I'm assuming the boat is long since sold, but I was wondering if you could help me as I have the 2018 version of that boat and I'm looking for info on where I can get the bimini top / covers / walls like your boat had - any info would be very much appreciated sir!!

-

Ahhh very good - that's the ideal setup for sure - someday but the kicker was the big item on the list this year - perhaps fish-hawk or bimini top next year - we'll see what gets approved at the budget committee meeting.

-

7 minutes ago, Rookie Fisherman said:

I had a tiller on that boat with a tie bar and a Trollmaster. Worked fine.

New boat has controls but I steer with my AP & throttle with iPilot.

good point Rookie - I steer with my electric motor as well. Found trying to run on just electric for propulsion and steering last year I was killing both batteries in 2 hours, and combine that with wanting a secondary engine for fishing offshore - the kicker was a no-brainer.

-

3 minutes ago, Steelydanh said:

Hello. If it's OK, I guess I'll join the party here.

New 2020 Targa Combo. Will be adding a kicker soon. Weather has been cold and wet, so not extremely excited about tearing things apart quite yet. Have yet to purchase the kicker. Bought a Suzuki 9.9 four stroke with controls/electric tilt about 2 years ago for my old boat. Good solid motor, but tends to surge here and there at trolling speeds. Runs around $2800 delivered. (It took about a day to rig the whole thing up.) I've read that Tohatsu makes the smaller Mercs, with a 9.9 Tohatsu w/controls, trim and tilt running about $2900 delivered. Tracker dealer near me quoted $4500 with a 9.9 Merc./controlls installed. Hmmmmmm. What to do? I see Cody is running a tiller model. What about you Rookie Fisherman? I like the remote as we fish in Canada quite a lot, and when I hear "Snag!", I can quickly kick it in reverse and be on my way back to retrieve a lure. Just wondering how difficult it is to run the shifter cables, etc. up to the helm. Thought about the itrolls, troll master, etc. to save the pain of running the cables. Keep coming back to wanting the controls next to me. Any thoughts?

New 2020 Targa Combo. Will be adding a kicker soon. Weather has been cold and wet, so not extremely excited about tearing things apart quite yet. Have yet to purchase the kicker. Bought a Suzuki 9.9 four stroke with controls/electric tilt about 2 years ago for my old boat. Good solid motor, but tends to surge here and there at trolling speeds. Runs around $2800 delivered. (It took about a day to rig the whole thing up.) I've read that Tohatsu makes the smaller Mercs, with a 9.9 Tohatsu w/controls, trim and tilt running about $2900 delivered. Tracker dealer near me quoted $4500 with a 9.9 Merc./controlls installed. Hmmmmmm. What to do? I see Cody is running a tiller model. What about you Rookie Fisherman? I like the remote as we fish in Canada quite a lot, and when I hear "Snag!", I can quickly kick it in reverse and be on my way back to retrieve a lure. Just wondering how difficult it is to run the shifter cables, etc. up to the helm. Thought about the itrolls, troll master, etc. to save the pain of running the cables. Keep coming back to wanting the controls next to me. Any thoughts?

Hey SteelyDan - I went with a Tiller model as well - I found the driver's seat and the main engine controls area a bit busy and I didn't want to add in a 2nd set - so I'm going with a 9.9 Evinrude kicker - 4 stroke with the e-trim/e-start/etc. I'm going to link the 2 motors with a bar so i can steer with the wheel - but have my first mate (my 10yr old) bump the throttle when needed. Keep me posted on your adventures on the 2020 version - still loving my 2018 with only one season on it so far!

-

20 minutes ago, Rookie Fisherman said:

On mine I was able to access the ares for the bolts through the rear storage compartment door, yours may be different.

I also had to relocate the u-bolt for the tie down strap as it was right where the motor hung.

10-4 - will look to see what access I have for sure - woke up to fresh 1" of snow and 50mph winds this AM

Boat is sleeping until the weekend I guess. I am hoping those black round discs in the splash pan near the big motor will give me enough access to get the nylock nuts and a socket wrench back there but I shall find out soon I'm sure. REALLY not wanting to pull up the floor if I can avoid it.

Boat is sleeping until the weekend I guess. I am hoping those black round discs in the splash pan near the big motor will give me enough access to get the nylock nuts and a socket wrench back there but I shall find out soon I'm sure. REALLY not wanting to pull up the floor if I can avoid it.

-

On 10/2/2018 at 4:54 AM, Rookie Fisherman said:

Went through this same process a few years back. Opted to take a 2x2 piece of pressure treated wood (painted it black)Set it in the on top of the transom in the throat of the motor bracket mount. This raised the motor 1.5" and did not have to cut the carpet or the deck. Had no effect on operation of the motor.

Also to save spaced at the helm I mounted the fish hawk at the back of the boat on a bracket in the versa track.

Hey Rookie Fisherman - I'm trying to use a plate that essentially does what you did with the block of wood - did you still not have to pull the flooring up to get access to the inside of the transom for the bolts on the kicker itself - or are you just using the clamps? Any info would be very much appreciated!!

-

Hey Cody - reviving an "old" thread - was actually looking online for what kind of mounting plates guys used for their kicker as I'm running into that same issue my 2018 V18 Combo - where that gap from the top of the transom into the 'throat' of the clamp on the motor - i was looking at a plate like the one attached but I see in one of the comments above inserting a block of wood painted black seemed to do the trick. So sounds like pulling up this floor/deck at the stern is going to be a bit of a pain in the ass - trying to print this thread out and sum up the tips / tricks (which I hugely appreciate) as I think I have to do the same to get access for the transom bolts (rookie guy me thought I could use lag screws vs. bolts).

Any other thoughts since doing it would be very much appreciated folks!! I am dreading popping up the floor on this still relatively new beauty!! lol

The plate below in the photo is the one plate I was looking at - and this one is the other: https://www.rnrd.com/marine-products/kicker-plates/. Essentially I would have to bolt the plate as well as do the transom bolts through the stern as well I think so I'm still pulling a floor up

2018 Tracker Targa V-18 WT setup

in This Old Boat

Posted

Happy 2022 fellow Tracker owners!! Just thought I'd tap this post as we get closer to March and even though us Northerners have a couple of months still before open water - anyone have any big plans / mods for the boat this summer? I still encountered water in the hull from time to time no matter how successful I thought I was last season, so we're going to hopefully get her in to the dealer and get the auto-bilge installed once and for all. Other than that hoping for just a good performance season on the water. I am starting to save to upgrade the graph as my son loves bass / walleye fishing so will have to start picking your brains about side scan / 360s / something a non-rich guy can look at reasonably - because after hearing what some of the panoptix systems cost - if I got one of those I might have to move into one of your basements! lol

Hope all is well with you all!