-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by Great_Laker

-

-

3/4 on Kings straight out from Oswego in 350-400’. 50’ down, orange spoons. Leadcore and dipseys. Nothing on riggers yet. Trolling north to south. Hoping to put a few more in the box before we head in.

-

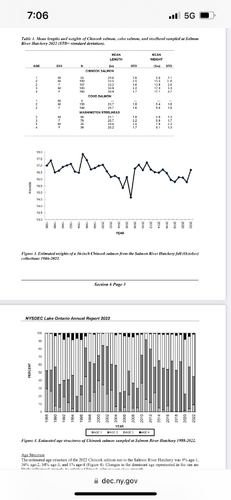

You can find a lot of the data you are looking for in the annual DEC Lake Ontario Report. It is usually about a year behind because the data is still being collected and analyzed. Look for the “Population Characteristics of Pacific Salmonids Collected at the Salmon River Hatchery” section. It gives an overview of the size and age of chinook collected every year.

https://dec.ny.gov/sites/default/files/2024-01/2022lakeontarioannualreport.pdf

-

Yes, you can crank them down as hard as you want. There is also a tab you can pull out on the Scotty pinch pad that makes the tension even tighter. No problem

-

1

1

-

-

On 5/13/2024 at 4:56 PM, cnyh2ofowler said:

I didn’t know they had lampreys in Mexico, they probably slither right through the border wall. Fished Oswego on Saturday, probably caught a dozen kings, no eels. Caught a laker with a tag in its back, called the number on the tag and are waiting for a callback.

Thanks for reporting the tagged Laker. If you want any information on it, send me a private message with the tag info and I can give you all the information I have on that fish if it’s one of ours. If you search for the post from Gambler about catching a tagged lake trout at Sandy Creek, you can read why we are tagging lake trout and what we are doing with that information. The external tag you saw indicates it has an acoustic tag inside the fish which is how we track them around the lake, sort of like underwater GPS.

-

In Lake Ontario (both US and Canada shores) Fisheries and Oceans Canada (DFO) treats tributaries for sea lamprey. COVID shut down the border and the Sea Lamprey Control Center (DFO) could not treat US tributaries of Lake Ontario because they could not cross into the U.S.. Lamprey wounding increased quite a bit during those years but started to decline in 2023 according to lake wide assessments. Sea lamprey are only in their parasitic adult life stage for about a year so changes should be pretty rapid once treatments resumed.

-

Fished 50’ to 15’ east of the port. 3/4 on browns and a bonus lamprey. Biggest brown came on two-faced stringer 22 down over 35 FOW on rigger. All others on boards in 20’ on green smithwick stick baits. Water around the port was 51 degrees and had good color. Further east was 46 degrees and clear. Speeds varied between 2.2 and 3.0. Trolling into and with waves both caught fish.

-

2

2

-

-

Electric USCG approved flares. Buy once, keep your old expired chemical flares as back ups.

-

No problem. A single NOCO 10amp charger that has three charging banks on it. Your 20 amp chargers will work just fine.

-

1

1

-

-

Yes that is ok to do. On 36V system we have all three LiFePo4 batteries charging at the same time without disconnecting the jumpers with a NOCO smart charger. When its colder than 32F the batteries will not charge FYI. The built in BMS shuts them off for charging, but they will still discharge it temps colder than 32.

-

1

1

-

-

Anyone run a thru-hull transducer in an aluminum boat? I’d like to be able to scan at 20-25 mph and my current Lowrance 3-1 transducer isn’t capable of doing that off the transom. I have it as close to the engine and as low as it can go without interference from the prop wash. I run a 20’ center console with Lowrance electronics. Looking for some advice.

-

-

Does anyone have surface water temps from Sackets harbor or Black River Bay? Thanks!

-

Great talking to you Brian. Thank you for letting us know you caught one of the tagged lakers and released it to collect more data. We tagged 320 lake trout this spring in all corners of Lake Ontario. Those orange tags are external markers so anglers know the fish have an internal acoustic tag. If you catch one of these lakers you are welcome to keep the fish but keep in mind the acoustic tags last for 10 years and we can collect movement data from that fish over that time period if you throw it back, up to you. We have about 500 acoustic receivers positioned around Lake Ontario on the lake floor and when a tagged fish swims near these receivers it lets us know when and at what depth the fish was at. This data is being used to quantify spawning locations at a full-lake scale and allows us to better understand spawning behaviors. Casey Prisco of Dirty Goose Charters helped us tag a large number of the lake trout on the U.S. shore this spring and you can check out his Facebook page if you want to see the full process from catch to tag to release. If you catch one of these lake trout, please call the number on the orange external tag and I will be glad to tell you when we tagged it and what location it came from on the lake. We have already had 3 lake trout recaptured by anglers who returned our tags. One was a Canadian tagged fish that was caught on the US side, these fish move large distances quick! Thanks again for spreading the word.

-

3

3

-

-

First problem is it’s a Merc, trade it in for any other brand and that should fix it. Second, check to see if each cylinder is firing correctly. You can troll on two cylinders without noticing a problem, it’s only after you hit higher RPMs that you will notice. Check plug wires, plugs, power packs. Hope it’s an easy fix!

-

He could use a bow mounted trolling motor like minnkota or Motorguide for auto pilot while his main motor provides thrust. On small light boats having the auto pilot on the stern makes for slow response time when winds and waves push you. Bow mounted autopilot on small boats gives you better control, you can also use it for spot lock when jigging. You pay about the same price for helm mounted autopilot vs a nice bow mount trolling motor and I think the auto pilot on a bow mount is an easier install for small boats and provides you with multiple uses. Either way, man is autopilot a game changer!

-

1

1

-

1

1

-

-

-

Same here. Temp sensor failed on x4d, free of charge, new one sent to my door. Let me keep my old one for a spare too. They have great customer service.

-

1

1

-

-

Try turning the pinch pad around so it releases out, not towards the board. Then when a fish hits, it will pull the line out of the pinch pad so it can’t dive. At that point it will only be connected at the back of the board, just like a yellow offshore planer board. If you twirl the line a couple times before you put it in the back pin l, it will keep the board from sliding all the way down the line to the fish once released.

-

-

Try tilting your fish hawk transducer at more of an angle towards the stern. If the blow back on your downrigger cables is too far back, the transducer may be intermittently reading the probe. That would make sense if the deeper you go the worse it gets.

-

-

-

First run of the season solo out of Oswego. Dumped the boat in after work at 4pm. Hooked into a brown, two coho, a Laker and lost another fish at the back of the boat, not sure what it was. Brown and first coho came on offshore boards in 20’ of water with bream color smithwick floater running west of lighthouse, 2.5 speed. Pushed out deeper around 6 pm. Second coho came on 3 color leadcore over 50’ on rod father warrior spoon. Laker was 30’ over 55’ with rigger on mixed veggie warrior spoon and the fish that spit the hook was the same set up, 2.2 at ball. Surface was 53 degrees around the lighthouse and same out in 50’. Lots of marks from 48-60. Fun night, flat ass calm after 6!

-

7

7

-

-

Docks at the launch are in now

Oswego 7/18

in New York Fishing Reports - Lake Ontario (South Shore)

Posted

Blue Leopard