-

Posts

238 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by 2lbperch

-

-

Yes, post some pics and a general synopsis of the product. I have heard good and bad about it. I always put in new stringers while replacing a transom, I cut 8" off the waterlogged string to pound in a 2x4 to help clamp the bottom of the new transom. I never have left the old glass. Fish FL, not worried about $ today. I'm not on a project right now. If you want some stuff let me know. I've got a dead cherry tree you can drop if you bring a saw and wedges with you. Works for me.

-

-

Yup, flapper wheel. Get the new wood done, all epoxied and fitting well, meaning square . Have it ready on the sawhorse. Mix a batch with some filler, can use ag lime if you didn't save dust, spread that on in a coat to fill in voids, clamp the new in letting the filler squish out. Fill the gap between the hull and wood with thickened epoxy also. Fabric over that at least 2 times, wrapping it forward 8" & 12". Looks like you've gotten after it. I didn't see any beer cans in the pics? Takes a few to get me in the grinding mood.

-

Use the website " search tempest". It will give you all the Craigslist ads for 1000 miles of what you type in the search bar. Hope they get caught, and didn't cut and hack the stuff.

-

Good place to try on a windy day. Harbor breakwalls protect it. Go deeper mid summer though. Tour the fort & the lighthouse, nice family day out. The launch is only 100 yards away from activities and fish.

-

Mr clean's Fair Haven Report

2lbperch replied to mrclean's topic in New York Fishing Reports - Lake Ontario (South Shore)

-

In pic #2, someone has been there in the past with a "repair"? Don't go crazy & cut everything. Start with a protractor set @ 3", follow the hull lines & cut there on the back. Get the plywood in. The inside near the stringers should be fixed 2nd. Fiberglass will not lose integrity until it is swollen and becomes waterlogged. Appears it is along the bottom on the inside. Get the transom in, grind the inside out after. Progress is good, any more questions, ask. Have fun.

-

-

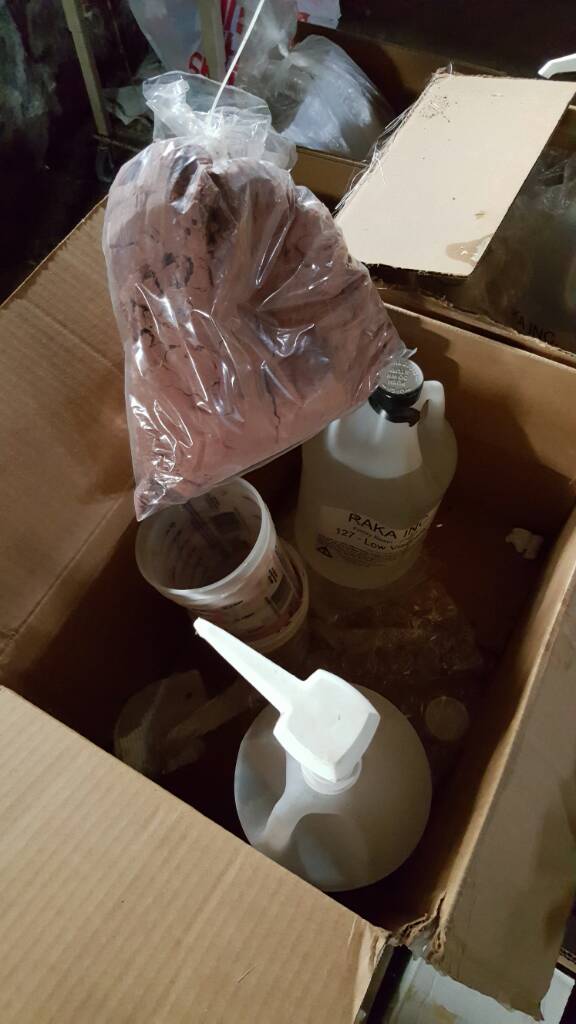

I have screwed some stuff up. It gets easier each time. Grind outside with a furnace fan behind you. Take the hottest shower you can stand, opens your skin pores to release the glass particles. Get gallons of acetone to keep things clean. The most important is to not get distracted, like getting interrupted while pumping the resin and hardener in the cup. Start over. Not fun grinding soft epoxy that won't set cause your drunk buddy had something so important to tell you. I've got lots of the powdered glass that sets up hard to use as structure filler, between the plywood cuts, and the easy sanding micro balloons for the finish work. Make some 3 foot clamps with 2×4's and threaded rod to hold the pieces tight while curing. A glorified wood clamp. I forgot who borrowed mine, or I'd loan em to you. Temperature is key, and always sand the blush off. The more humidity, the worse it is.

-

-

-

Looking for report on Southern Cayuga launches

2lbperch replied to On the Hook's topic in Finger Lakes Discussion

Yes, union springs is good to go also. Water is up and one ramp is debris free. Was there today. -

You can grind the whole back of the transom off also. Just leave 3 inches fillet around the outside of the hull that you can blend the new glass into. When its cut out, grind from the corners and bottom to an edge that will cut you, leaving at least 3 inches of original material. That equals 1 piece transom wood and no air pockets in the work. Cover the back with four pieces of fabric staggering the orientation so it crosses around 45 degrees to one another.

-

Yes. A cover crop is beneficial for a few reasons. It holds the soil preventing erosion during snow melt and heavy spring rains, the roots keep heavy clay soil a bit looser allowing it to breathe. (keeps the beneficial bacteria in the soil happy) It is also a nitrogen factory at a minimal cost. The best thing that it does is creates more organic material in the topsoil layer. O.M. effects the many organisms living in the dirt in a good way. It makes a less sterile environment for the little party in the soil to rock if you watched it under a microscope. The extra O.M. it gives is best, the free nitrogen is a bonus. The different types of cover crops is a whole new topic. Rye needs to be plowed under or sprayed to kill it, after breaking down, the N is available to other plants. Oats get killed by a hard frost, no plowing or extra spray. My farm is minimal tillage, oats win. A dairy needs tillage to incorporate the manure into the dirt, rye wins for them. The different crops need different amounts of N. Corn needs lots, a form of grass. I apply 40 to 50 gallons per acre of a solution containing 32% nitrate. Soybeans need little to none, legumes make their own. In the end all nitrogen goes down and down into the ground and leaches. Nothing can stop that. It rides down into the ground water bit by bit with rain. It only stays if a plant has consumed it. That is world's different than a river of manure dumping into a creek. Injecting fertilizer puts it where the plant roots can access it faster with minimal surface erosion loss. That cover crop helps, but in the end, not enough N to grow a crop of corn. But if you see something growing, it is consuming and holding nitrogen, keeping it out of the lake. Sorry for the book guys.

-

Lakebound88 did it the right way. No smaller than 10AWG. That means less resistance. Copper strand wire, heat shrink tubing on all connections, triple shrink to be sure. I have stereo cables I could build myself that cost hundreds, the hot, neutral, ground wires are braided together like a ponytail to pull on. Twist your wires tight together in case a foot or a stretch event happens, like a twizzler or rope, heat shrink each single wire connection , and then again for a double wire connection. Just let the single connect shrink hang out a 1/2" on each end. You won't worry about any wire till you have to scrub the battery terminals. A power block is so handy to tap into. Bailed me out many times when something thinks for itself.

-

Yes, phosphorus, when it's in it's best state, good. That is naturally in the ground, but farms usually put 7 to 10 gallons per acre on in the nitrogen recipe before or while planting. It will bond with opposing ions in the dirt & not leech. Too much will, it is a neutral, essential to good plant health. I'll let it out. I'm a cash crop corn/soybean farmer. The only animal on the farm is me. Phosphates are toxic to almost everything under the water also. Good point HERMIT. CARBON, sorry, caplock works here, will absorb phosphates. Agree, phosphorous is more concentrated than any lakes carbon level can absorb it if the phosphates run off. All my stuff is injected into the dirt. It bonds with + & - charges to stay attached to the soil, most of the time. After harvest bacteria eats the stubble and turns it to carbon which returns P into the soil. Bad if you fall plow or bale the crop residue. I love Seneca lake. Herm does have a fact, phosphates kill almost everything in water in a concentrated dose. More than a cow**** ammonia foam runoff. We can get back on topic. What is the real deal on "heartbreak lake"? In 10 years I'll figure it will be the new norm. Tight lines for the future.

-

That's too bad about the manure. That is a ammonia spike in the water "toxic to fish". Bacteria consume it to nitrite, still toxic to fish. Another bacteria eats that, becomes nitrate, what most grain farmers use. Toxic in high levels to fish. Nitrogen gets used by bacteria and plants. The 2 ,4 ,D, that almost all farmers spike spray with does more damage, also in the weed control fertilizer people spread on the lawn. It's got a month cycle, on land or water. Bacteria eats nitro, just needs time to get established. Nothing eats 2 4 D but time. I would rather have cow excrement "ammonia" than field spray. Round up is a salt, 3 or 4 specks on the growing point is enough to kill a plant. Don't paint your weeds, no need. Sorry, sounds like I'm taking care of a fish tank, but that lake is one of my favorite tanks.

-

-

Mr clean's Fair Haven Report

2lbperch replied to mrclean's topic in New York Fishing Reports - Lake Ontario (South Shore)

Yes you can launch over there at the limestone rock wall with the stop sign attached to the yellow gate. If you have the foot paddles, might be tricky, it's all gravel and it shifts around frequently. The State Park boat launch in the bay is very nice. About 1 1/2 X to the channel. Still only 100 yards or so. -

You have to get out a little deeper for the smallmouth now days. Usually start around 40 to 60 ft and drift to 20 mid summertime. Some days deeper. Drift with a mushroom anchor, concrete in a coffee can, dragging a gravel bottom, & cast rubber crawdads in the cloud the drag makes works for me. Pull up the drag and keep drifting over the spot till it slows down, drag again.

-

Leeches or dead minnows that you drag across a sand, mud bottom.

-

What section of lake Ontario are you interested in? I shoreline for largemouth in the bays. The most fun is smallmouth in the lake.

-

Support the chines along the back of the boat, and the lifting rakes in the front with some blocking. When you cut the floor and stringers out, the center of the hull tries to spring up, pushing the chines and rakes down. If the trailer is well bunked with wide boards, it may not be an issue. On faster boats this makes them ill handling at higher speed if gets out of whack. Before you take the top off, you need 3 2x4's hold the sides from bowing out. You have to work around them. You take them out when the top is back on. If you don't, you will have a hull with new wood, and a top that will never fit back on the boat. It is nothing you can't prevent. Take your time, lots of measurements, lots of pictures with the tape measure in the pic.

-

If you use fast hardener in the epoxy mix you can work down to 50 degrees. Still needs 24 hours of temp 50 or higher to set up hard. If you are using med or slow hardener, wait till it's 65 out at least. It will effect the strengh. Do all you can in a buddies garage, like the transom pieces. Before you go crazy cutting everything out, support the bottom of the boat so the trailer bunks don't push the hull out of shape.