dbitting

Members-

Posts

80 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

dbitting's Achievements

16

Reputation

-

I bought a machine and made the soft top myself over winter the first time just used the old one as a pattern. This time around i have a solid frame and not a bimini frame so i have to make it from patterns. Sailrite has some great videos on ow to make lots of thins related to fabric and canvas best of all is if you buy the supplies from then and have questions they will help you.

-

I started this very process where i taught myself to weld stainless steel with a TIG welder then bought a bender and fabricated a frame. I mounted it to the boat. worked out very well. Then i took 2 sided canvas tape and stuck plastic film sheet( durascrim) to the frame. when i got the shape i wanted i placed canvas over the plastic and pulled it tight making the top i wanted. Mixed up some polyester resin and coated the canvas until it soaked through the canvas. after placing several layers of weaved fiberglass and chopped mat over it you let it dry several hours to a day depending on the temp. when dry you peal the top off and remove the plastic. sand and paint the top and mount. on a side note the top add weight above the center of gravity so be careful as you will feel a difference on the water due to the weight you add over your head. I tow my boat so this season i decided to go back to a canvas enclosure because of the added weight and wind resistance. Sailrite has all the canvas and plastics well as the tools you need minus the fiberglass. If you have any questions feel free to PM me

-

Conversion from points to electronic ignition OMC

dbitting replied to Gill-T's topic in This Old Boat

The draw from your riggers are causing the RPMs to dip and probably stalling the motor. I found in My OMC 4.3 it was difficult shifting. the RPMs have to be way low for it to shift properly. I ended up eliminating the OMC ignition ag getting a GM electronic ignition and coil. taking out the electronic shift module and just using a microswitch to blip the coil. I eventually abandoned the OMC and converted to alpha one drive. problem solved! This season i will be removing All OMC stern drive and replacing with Alpha 1 Gen2 unit. I will be placing the OMC to Alpha conversion kit up for sale in Spring -

I have fished a Tracker SuperGuide V16 for 12 plus years. I have fished lakes in PA as well as the Big D in Easton and Philly and Sandy Hook, NJ in the Bay. Being prepared is is the key. While you can look at the weather reports all you want there is going to be that time where a storm will roll in and catch you with your pants down. While i would not suggest planning a trip in bad weather you could probably be safe in all the mentioned bodies of water./ Be prepared and be sure you boat is capable of handling water ingestion. Since your boat does not have self bailing deck I would recommend ay least 2 1100GPH or higher with Automatic features. a self inflating life jacket and since you mentioned you fish alone a wireless MOB device ($199). I like to cover my bow when I fish alone that way if I hit bad weather and the waves come over the bow most of the water will shed off the boat and not in it. If you plan on recovering the floor be sure to add flotation foam in open cavities. As far a a bait well as much as you would want to put it at the stern you may want to test the weight distribution before committing to its location. A stern laden boat can take a wave over the back and not recover! I have since sold the V16 and moved up to a PennYan 212 and do more salt water fishing. I apply all the mentioned suggestions and have gone out 20 miles off shore to the wrecks and manage a 70mile trip from wreck to wreck this past Summer. The same area we went out in a 21ft center console and hit a storm, Totally different experience we were soaked water everywhere water over the bow etc. we took our time and applied common sense and we made it to the dock just fine. You have to be comfortable on the water, when S#!t hits the fan you are prepared. I see guys go out in SH Bay with 14ft jon boats,( while I think that is insane) and they manage to get back.

-

Have you tried adjusting the angle of the transducer to be parallel to the bottom. Maybe it is at the wrong angle.

-

What's a ransomware attack? Hackers use ransomware -- a type of malware -- to scramble a company's computer data and hold it hostage until a ransom is paid. In a double extortion scheme, the attackers pilfer the data and threaten to publish it. On Thursday, Bloomberg reported that Colonial paid nearly $5 million in ransom for software to decrypt its computers. The report contradicted an earlier story by The Washington Post that the company was restoring its data from backups and didn't plan to pay the hackers. Bloomberg reported the software tool, which was paid for with an unspecified cryptocurrency, was slow so Colonial continued restoring its system from backups. The above was from CNET and the first statement is not totally correct. it is usually an encryption app that is run on the network and the hacker holds the key releasing it to you when the ransom is paid. if you have backups and are up to date or run volume shadow services on you drives you have very good chance you won't have to pay. The hackers are now seeking out Backups and if found the process them first and follow up with the live data.

-

This is nothing new and has been going on for quite some time. We were hit a few years back on a Saturday morning and in 4 hours all of our data was encrypted with a note. that note included an email to contact and see what the ransom was to unlock the files again. We didn't have to pay that because we had a good backup system. As I mentioned in MANY cased it is a malicious code that is logins against your system and once it has found access it does it's thing. I worked closely with a forensic team trying to determine how and where it got through but because I reacted quickly i may have destroyed the evidence showing the how and where. RDP (Windows Remote Desktop) is one of the ways to access the companies FTP servers or any other unsecure port gives these thieves a portal to your network. Simply closing a popup or replying to an email creatively constructed can give them the information they need. Be sure in most cases it starts with a username and password. Google Ransomware and do some reading. As mentioned you will start to see MFA (Multi factor Authentication) where you enter a username and password and you will be sent a code or get a phone call confirming you requested access. Remember people are lazy they don't want long and sophisticated password and these people exploit it. This could be a whole topic in itself

-

Sadly I would bet it was a weak password is actually of they got in. If it was Ramsomeware chances are it was banging away at their routers with simple usernames and password. common are admin, root, administrator with the same as the name for the password or even just password. where I work I get about 1.7M hits on our router trying to get in and we really have nothing of importance to the outside, However if the manage to get in and encrypt all your files they can charge whatever they want to unlock your files. Since most ask for Bit Coin it becomes untraceable. companies pay thousands to millions depending on how much was encrypted. and companies PAY IT!

-

I just recent spent this season trying to find the correct prop for my rig. I recently completely had my 4.3l rebuilt and swapped my OMC drive to an Alpha 1 Gen 2 unit. with that said there was no prop with the new unit so i started with the old OMC prop that was on the old drive. 15x17 was my starting point. i recorded my speed and WOT rpm then went to that same site. I found the dry weigh of my boat and entered in all the information. I think the initial. recommendation was a 14x17 if i remember however it was not even close is wa at the MAX RPM of the engine recommended by the builder at WOT and on plain. OMC recommend the WOT should be at 4600 rpm. for every inch in pitch the rpm decreases about 150 rpm for every inch of diameter the rpms should decrease 500rpm. I found there are way too many factors to follow a chart. I suggest weighing the boat empty first then add all your gear you normally would put in on a trip add in the weight persons on board on a normal trip and tune the boat with that weight on at time of testing. You boat will perform different when your are alon than when 4 people are onboard. props are give and take, you cannot have a holeshote and ttop speed at the same time. In my case I started at a 14x17 and went all the way up to a 14x 21 and finally settled in at a 14x19. Turning Point recommended the 14x21 but it just didn't work the way i liked. I went with the 4 blade aluminium basically i wanted the 4 blade torque to have punch in the waves on the ocean however i didn't want to give up a bunch of top end. I didnt even venture into SS props as i am know to tear up several per season. this summer alone i had 3 strikes on my blades that i never saw the submerged objects 2 I felt as i passed over them but the 3rd may have been a sea creature as the blade was trashed but no signs of impact wothe the normal hard object. I fish river where they are tidal waters and the amount of S@#t floating is amazing. In the end i settled with a TP Hustler 4 blade 14x19 prop the plains quickly and i still can get 30 to 34mph top speed at 4600RPM WOT properly trimmed. BTW the prop calculator indicated a top speed of 45MPH LOL not even close! I hope this hepls

-

great videos. I would recommend COOSA Board for your project if you are tearing the boat down this far. with 2 layers of fiberglass on each side of the boards altering the weave you could gain so much strength and reduce weight at the same time while making that boat impervious to water. it is a bit more money but i think easier to work with. This product will hold no water, never rots. there are videos on youtube ( boatworks today) that show how he used it to make his side panels and transom. I did my transom this year with it and it worked out great. if you are replacing the flotation foam find the highst density closed cell foam available and you will also eliminate water soaking it. Ebay has ost of the fiberglass and foam needs. I can send you the info from where i purchased what i used.

-

a bit old to answer but YES it works. for your boat you will have to modify the panel to your cuddy, i built a box around the opening and mounted the electronics in the box inside the cuddy it works great simple to install $1300 for AP

-

Looking to buy a fishfinder

dbitting replied to Triumphchaos83's topic in Questions About Trout & Salmon Trolling?

-

Looking to buy a fishfinder

dbitting replied to Triumphchaos83's topic in Questions About Trout & Salmon Trolling?

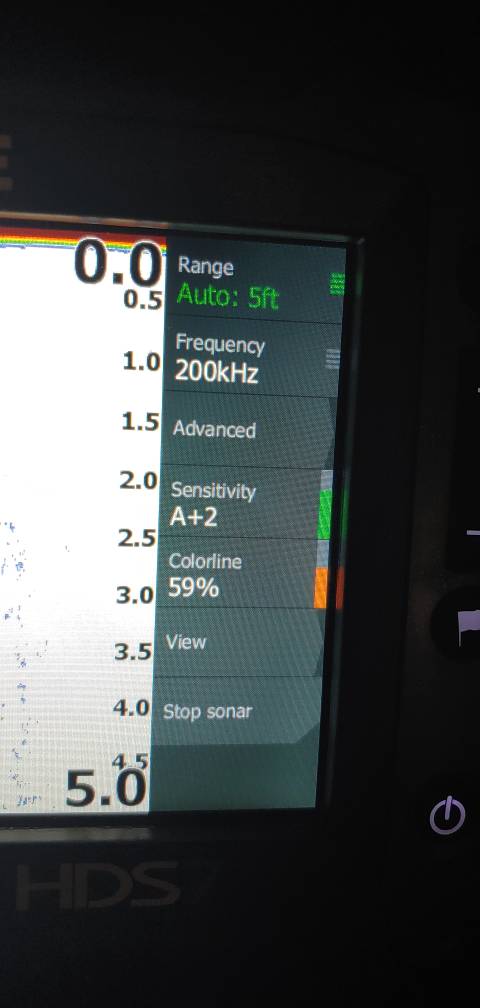

Are you planning Autopilot in the future? if so look at Lowrance as they offer the cheapest package for adding autopilot ( outboard and Motorguide xi5) the trolling motor offers anchor lock I bought 2 HDS9 Carbons. GPS antenna integrated Audio networking and autopilot ( cable steering) $4500 last year. This is more that you are looking for but i started with that question and was very disappointed quickly at the small screen. too much information ti fit sonar and chart on at the same time. I will say if Hummingbird had a reasonable Autopilot that would have been my first choice. their screens are really clear and offer mega imaging SSandDI -

-

I use the HDS 9 Dual screen with an 83/200HD and a total scan transducer.My setup y has the capability to connect up 4 transducers, however currently i only use two and mosty this year the side and downscan 455KHZ I can say when you learn how to set up the SS/DS and get to know how to use it. fish finding has a whole new meaning. as mentioned th 50,83 and 200 have a cone that projects out and gets larger as you get deeper, however the 455/800 SS and DI create a SLICE behind your boat to the left and right of the stern creating a picture of the water column and the bottom. When ou find something like bate or marks you simply touch it press the flag and create WP. for me i then create a rout and use my autopilot to troll wher i think the fish are. Lowrance has a new LIVE IMAGE transducer but it is pricey $999 i think it is.