lrg355

Members-

Posts

723 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by lrg355

-

Fuel system condition on 1985 Sea Nymph 195 restoration

lrg355 replied to lrg355's topic in This Old Boat

-

Fuel system condition on 1985 Sea Nymph 195 restoration

lrg355 replied to lrg355's topic in This Old Boat

I am putting on a new 23 Yamaha VF90 so I want to get the fuel system in perfect order. All hoses and fittings will be new. As for the paper under the tank, it had the consistency of the brown sealing tape but was in sheet form. Had what appeared to be fiberglass reinforcing thread running the total width. I was just wondering what its specific purpose was other than just possible cushioning to protect the tank from rivet heads which can make contact. -

Pulled out the gas tank today. Fuel fill hose is completely disintegrated. Fuel fill nozzle also in poor shape. Broke off trying to remove hose. Maybe ethanol use helped disintegration. Obvious where all particulate matter in the gas tank came from. Fill on this boat like others in the late 80's is in the transom splashwell. Inside of the hose is as bad as the outside. Also, gas tank well was lined with a paper that looked like the brown reinforced packaging tape. Any ideas what this is and where it may be available? A shame Sea Nymph didnt have the sense to use all stainless clamps. Screws on the clamps were steel and couldn't be removed. Had to cut off.

-

-

-

Put a long wire wrap into the elbow tube this morning. It went around the corner and about 6 inches down, so no ball valve in the elbow fitting. Tank is about 8 inches deep. Plan A was to get the fitting and tube out without damaging the tank. That failed! Tube is completely blocked. Plan B was to get more aggressive with compressed air to 120psi and pulse it if necessary. Plan C. Drill a .159 hole on top center of the elbow and put a 1/8 or 5/32 rod down and poke out the obstruction. Than, tap the hole for 10-32 and put a plug in it. Plan D Drill the elbow fitting out as previously described. Luckily , plan B worked. Plumbed the compressor directly into the 1/4 NPT elbow . Turned the valve on at 80 psi, cranked up the regulator and it let go at 100psi. I think there may have been a completely plugged screen in the tube. I am going to take the tank out for a good cleaning. Lots or rubber particles in there, probably from the dry rotted looking fill hose. FINALLY SUCCESS! Thanks for all the input from everyone.

-

More searching online adds a bit more information. That large 1 1/4 nut is holding the bushing or sleeve in place. The OD of the bushing is 3/4 thread. The ID of the bushing is 3/8 NPT female thread. The opposite end of the bushing is flanged, about 1 1/4 Dia with two flats machined on the flange. That is inside the tank. There are two protrusions molded into the tank that the flats on the inner flange fit between. That is what keeps the bushing from rotating. I an getting about 15 degrees of rotation of the bushing now after being excessive on trying to unscrew the elbow fitting. Had very little rotation of the bushing when I started. The elbow fitting is 3/8 Male NPT threaded into the bushing with 1/4 female NPT out to the motor as you can see in the picture. Inside the tank and inside the 3/8 NPT Male end of the elbow is a barbed fitting with a plastic pickup tube to the bottom of the tank. This pickup tube and elbow fitting is very available online. Some tubes have a screen on the end and some have a sintered.metal filter while others have nothing. Mine obviously has something that is severely plugged. Cant find any ordering info on the sleeve. Problem is 38 years of corrosion etc and aluminum on aluminum galls up the treads. Going to take the tank out and get all gas out and clean out to get all possible fumes out. Last resort will be to CAREFULLY drill down thru the top and step drill up to near the diameter of the tap drill for a 3/8 NPT. Since there is a hole in the middle, the drilling should stay concentric. With a thin wall from the now larger ID to the threads, it should collapse and break free. Wish me luck!!

-

Looked further online Some have just the tube but some have a filter on the end of the tube. It looks like the filter that is in the gun of an oil burner, sintered.metal. I have one in my Beckett oil burner gun. Also used as mufflers on air line exhaust. There is probably one on the tip of my pickup tube. Got to get the pickup tube out without ruining the tank. I've tried blowing in with 80 psi air. No luck. Must come out

-

I had about 3/4 tank full of old 2 stroke mix in the tank of my project boat. Removed the sending unit to have a peek inside. Couldn't see much except 3/4 full tank. Decided to siphon it out. Put a hose on the fitting, ran it thru transom drain hole to a 5 gal can. Had a few cans ready. Tank is 24 gal. Tried to siphon it, no luck plugged tight. Tried to blow in, no luck, plugged tight. Put the hose in the sending unit hole and siphoned about 15 gal. So the pickup tube is blocked or has some type of valve or filter that is blocked. Ok, now try to take out pickup tube and elbow fitting on top. No luck again. Time to look at YouTube to see how this disassembles. It shows that the top elbow fitting should screw out of the " sleeve" fitting on the tank. Cleaned it up, put on AeroKroil penetrating fluid. Waited a few hours. Held the 1 1/4 nut and tried to unscrew elbow fitting. No luck, stressing it to the point of breaking something so I now hesitated. Does anybody have any experience with this fitting and pickup tube removal? This is a poly tank made by Kracor. This is on a 1985 Sea Nymph 195.

-

I had about 3/4 tank full of old 2 stroke mix in the tank of my project boat. Removed the sending unit to have a peek inside. Couldn't see much except 3/4 full tank. Decided to siphon it out. Put a hose on the fitting, ran it thru transom drain hole to a 5 gal can. Had a few cans ready. Tank is 24 gal. Tried to siphon it, no luck plugged tight. Tried to blow in, no luck, plugged tight. Put the hose in the sending unit hole and siphoned about 15 gal. So the pickup tube is blocked or has some type of valve or filter that is blocked. Ok, now try to take out pickup tube and elbow fitting on top. No luck again. Time to look at YouTube to see how this disassembles. It shows that the top elbow fitting should screw out of the " sleeve" fitting on the tank. Cleaned it up, put on AeroKroil penetrating fluid. Waited a few hours. Held the 1 1/4 nut and tried to unscrew elbow fitting. No luck, stressing it to the point of breaking something so I now hesitated. Does anybody have any experience with this fitting and pickup tube removal? This is a poly tank made by Kracor. This is on a 1985 Sea Nymph 195.

-

Tore the floor up today. Lots of critters had been living there. Floor was 15/32. Many people ask about the gas tank. This is a plastic 24 gal. Boat is an 1985. The floor removed ended at the first wall at the transom. There are covers there so l removed one. Solid foam behind the cover. There is a piece of plywood under it. The edge is only visible. Would be very difficult to replace. Has anybody done anything with that final piece of plywood? Boat would not fit in the garage so l built a tent type cover. Nice and warm in there.

-

-

As I had mentioned before, my neighbor has an 89 GLS 195 with the 90 Yamaha VMAX SHO and it is a great setup. I fish with it often. Does everything right from trolling all day without a sputter to cruising at 4k rpm and nearly 8 mpg. Really seats you back in the seat out of the hole. All around impressive performance with no noticeable negatives. It is connected to a NEMA 2000 backbone to his Lowrance HDS Carbon so all gauges, performance and data is available on the screen. Great setup

-

-

Floor material for aluminum boat instead of dreaded plywood

lrg355 replied to lrg355's topic in This Old Boat

-

-

-

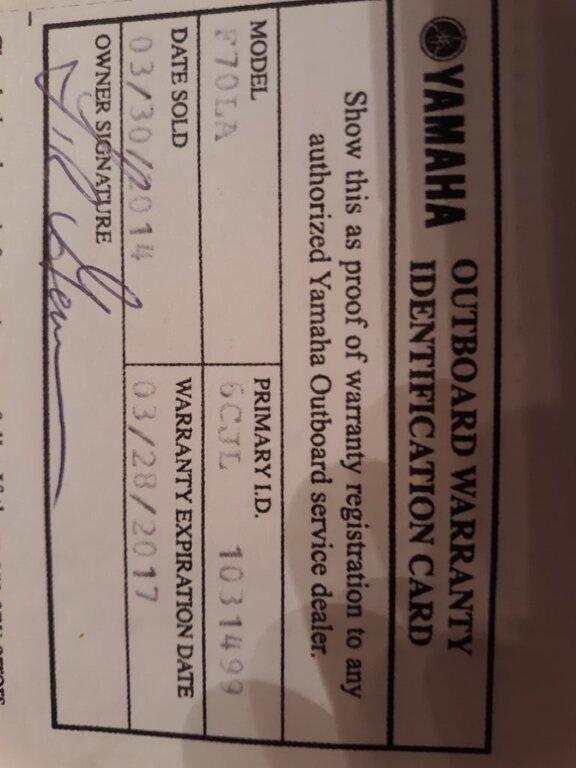

for sale : usa Yamaha F70LA four stroke for sale. SOLD

lrg355 posted a topic in Classifieds - Buy, Sell, Trade or Rent

I am selling one of my two Yamaha F70LA fuel injected 4 stroke outboards. One is currently on a Sea Nymph GLS175 and has 440 hrs. This is actual hrs as shown by the ECU on the N2000 network on my Lowrance. The other is on a 21 foot Pontoon which has been used very infrequently. It should have under 100 hrs. Both motors are in excellent condition and have NEVER had any issues. Both were bought new in 2014. Non ethanol fuel has only been used in both. All recommended maintenance has always been completed. $5250 for the 440 hrs motor or $5750 for the lower hrs motor. Your choice, but only selling one. Both are currently in storage and will be available in late March -

Pulled up the rug today. Ripped out a lot of other items that must go also. One of the previous owners mounted many things with common steel screws, not stainless. Removal was a chore with grinding screw heads off or drilling them out. The floor is riveted down and from from the factory rivets on the console, I believe this is the factory carpet and floor because nothing looks like it was ever removed. This is a 1985 so it is about 38 years old. Unbelievably, the floor is solid, no soft spots or rot anywhere. Some slight surface delamination in a small spot. Considering letting it dry completely for a month or so, repairing the delaminated area, sealing the surface than covering with Nautilux marine vinyl.

-

-

-

-

Has anybody used aluminum instead of plywood for flooring when restoring a Sea Nymph 195? If so, what gauge sheet did you use and what type(alloy)? If anyone has a 93 or later with an aluminum floor, is it possible to check an edge with a micrometer or calipers? I would guess it would be 12 ya (,080) type 5052-H32 so similar. Would be good to actually know rather than estimating